Understanding Multi Echelon Inventory Optimization

| View From The Ridge: 15 |

July 2, 2015 |

Rod Daugherty

Vice President, Product Strategy

Optimize Your Multi-Echelon Inventory Investment

If your company has a network configuration where a higher-level node, such as a national or regional distribution center, services downstream customer-facing stores or distribution centers, then you have a multi-echelon network. That’s easy so far, right?

What makes a significant difference to the profitability of your enterprise is how you optimize the inventory investment for your multi-echelon network. True multi-echelon inventory optimization seamlessly manages your demand and supply plan.

What is the Business Problem?

This may seem straight forward, but the devil is always in the details. The fundamental business problem is, “how do you provide the desired service level to your customer while maintaining the most profitable inventory investment across the entire enterprise?” If you have an older less optimal replenishment solution, you might be forecasting and replenishing independently for each echelon. In other words, you might be performing replenishment for the stores or customer-facing DCs separately from the distribution center that supplies your stores or customer-facing DCs. This results in silos of inventory that have no visibility to each other. Ultimately, this will lead to too much inventory. One problem with this method is you are treating sales from the supplying DC as demand. In the below scenario, there is actually only one source of demand- and that is the customer that purchases from the store or customer-facing DC. There is a much better way.

Multi-echelon network

What is the proper solution?

Blue Ridge Supply Chain Planning provides true multi-echelon inventory optimization (MEIO) that properly addresses these problems so that demand planning and replenishment optimization are performed for the enterprise in one single optimization exercise rather than multiple sequential sub-exercises for each echelon.

Initially, using the silo approach for MEIO, pictured on the top in the graphic above, looks…sort of correct. However, on closer examination, we note there is no connection between the store silo and the DC silo. But simply making that connection is not the answer (though some software providers have tried to do exactly that). Demand, replenishment, and inventory optimization must be architected properly to enable MEIO.

MEIO solves the entire inventory investment problem holistically, starting with the demand forecast at the customer-facing echelon. Demand and inventory planning decisions are made at the enterprise level in one single optimization exercise (as in the picture on the bottom) rather than in a sequence of sub-optimal exercises for each echelon as in the silo approach.

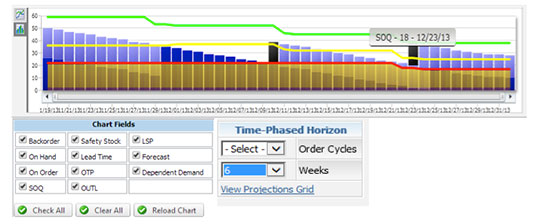

Time-phased joined order projections

One of the most significant components to enabling MEIO is joined order projections. Remember, the key is to view the inventory for the entire enterprise as one investment, not as separate siloes- one for customer-facing locations, and another for distribution center locations. To do this, the Blue Ridge Supply Chain Planning MEIO solution starts with all segments of the forecast at the customer-facing echelon, for example, a store or customer-facing DC. It takes into account seasonality, trend, daily profile if applicable, and event uplift.

Next, the solution projects demand forecasts and considers committed quantities, expected receipts, inventory positions, moves a day ahead and computes the next inventory position, low stock point, order up to level and suggested order quantity.

Then the solution calculates time-phased, joined item/location order projections (order forecast), expected receipts, and inventory positions for every day in the configured planning horizon. A key differentiator in Supply Chain Planning is the use of joined order logic in the calculation of the order projections (order forecast.) This enables the solution to precisely plan day-by-day into the future with unprecedented accuracy.

Time-phased joined order projections

The Blue Ridge multi-echelon inventory optimization solution:

- Avoids multiple independent forecast updates in each echelon (and instead uses time-phased, joined order projections).

- Accounts for lead time and lead time deviation for every item at each location and echelon.

- Exploits the full visibility of all demand drivers up and down the supply chain when performing automatic constrained supply allocation.

- Coordinates the demand and supply plan to support seasonality, promotion, and causality in a properly layered total forecast.

- Offers different service levels for every item at each location and echelon.

- Utilizes multi-echelon science to optimally deploy inventory in the network.

The bottom line

Blue Ridge does the heavy lifting and enables planners, analysts, and buyers to manage their daily work through exceptions and alerts while managing your inventory investment for optimum profit.

Comments are closed.