Reduce Inventory Through Proper Lead Time Management

| View From The Ridge: 33 |

November 06, 2015 |

Tracy Coon

Supply Chain Education Consultant

At some point we’ve all been asked to reduce inventory and our first reaction has likely been to reduce our item’s service level settings, make Global Control adjustments, or simply stop buying. Unfortunately, these reactions tend not to produce the desired result; especially long term.

Looking to lead time isn’t generally one of our first thoughts to reduce inventory. In fact, most companies skip right over lead times in their efforts to reduce inventory. So, why are lead times so often overlooked?

Theory vs. Reality

You’ve probably heard us refer to lead time as the ‘sleeper component’. In the past, inflated lead time has been difficult to identify because it doesn’t stand out in your layered inventory reports (safety stock, cycle stock, promotion, investment, overstock, etc.), and because it’s never been considered a layer of inventory, it can easily go unnoticed.

In theory, lead time is never in stock, but rather it’s always in transit. The reality is that everyone has some amount of lead time in stock. The goal here is to make sure that any lead time that’s in stock is valid.

The 2 for 1 Impact

Lead time is a component of your item’s OUTL build. It is also one of the five major components used in the safety stock calculation. If your lead time is inflated, you’re not just buying too far in advance. It is actually increasing your safety stock requirement and adding additional quantity here. This means your inflated lead time is hitting the OUTL twice!

Seek out the Opportunities

There are now a variety of much easier ways to identify inflated lead times. Supply Chain Planning (SCP) now has the ability to calculate and manage lead times through our new function: Lead Time Forecasting. This simplifies the process of seeking out suppliers/items where lead times have become inflated, or understated, and allows a systematic option to manage your lead times based on actual days versus expected. This eliminates the risk of guesswork and human error. SCP can now calculate lead time days and deviation, similar to how demand deviation is calculated. Contact a member of our Blue Ridge team to find out how you can begin taking advantage of this new function.

Supply Chain Analytics (SCA) reports are also helpful for managing lead time.. One of my favorites is the Lead Time Forecasting Management report. This assists you in easily identifying suppliers or items where there’s a difference between the Total lead time days and the actual average lead time days.

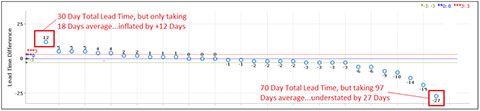

The positive values represent the average number of days the Total Lead Time is inflated over the average. These supplier/items are contributing to your excess inventory. The negative values represent the average number of days the Total Lead Time is understated from the actual average lead time days. These items are most likely costing you out of stocks today.

Where to Begin

First, find an existing lead time report, or build one from scratch. Review the suppliers/items where the greatest opportunity exists. Be sure to include cost in your report so you can go after what’s costing you the most first. Resolving these suppliers/items will have a quick impact on your inventory reduction. Then, continue with the rest.

And as a Reminder…

Curious about your lead time opportunities? Use SCA to identify suppliers/items with inflated or understated lead times. Validate and make corrections where needed. And as always, the team here at Blue Ridge is ready to assist you in making Supply Chain Planning a great profession!

Comments are closed.